- Nederlands, Belgique / België

- Česky, Česká republika

- Deutsch, Deutschland

- Español, España

- Português, Portugal

- English, Europe

- Français, France

- Italiano, Italia

- Magyar, Magyarország

- Nederlands, Nederland

- Deutsch, Österreich

- Polski, Polska

- Română, România

- Français / Deutsch, Suisse / Schweiz

- Svenska, Sverige

- Suomeksi, Suomi

- Türkçe, Türkiye

- English, United Kingdom

- Slovenská, Slovak

-

Worldwide

- Alla Utvalda produkter

- QuantuMike

- LEGEX Takumi

- STRATO-Active-serien

- Measurlink 10

- TAGLENS

- MCOSMOS 5

- Crysta Apex V

- Formtracer Avant

- MiSTAR 555

- Skjutmått

- Bluetooth dataöverföring

- QuickVision Pro

- Alla Produkter efter Industri

- Flygindustri

- Medicinteknik

- Fordonsindustri

- Energi

- Tillverkningsindustrin

- Elektronik

- Original Equipment Manufacturers (OEM)

- Fallstudier

- Alla Handmätdon

- Skjutmått

- Mikrometrar & Mikrometerhuvuden

- Mätdon för invändig mätning

- Mätdon för djupmätning

- Höjdmått

- Indikerande mätdon och Skänkelmätur

- Specialutrustning

- Utrustning för kalibrering

- Passbitar

- Alla Koordinatmätmaskiner

- Små och mellanstora koordinatmätmaskiner

- Koordinatmätmaskiner för inline-mätning

- Stora koordinatmätmaskiner

- CMM Rotationsbord

- Prober

- Mätspetsar

- Fixturer

- Inkapslingar

- CMM Programvara

- Alla Visionmätsystem

- Manuella 2D Visionsystem

- Manuella 3D Visionsystem

- 3D CNC Visionsystem

- 3D CNC Multisensor Visionsystem

- MiSCAN Visionsystem

- 3D CNC Visionsystem för mikrogeometrier

- Vision System Software

- Tillbehör till Visionsystem

- Fixturer för Visionsystem

- Mätspetsar för Visionsystem

- Alla Optiska mätsystem

- Luppar

- Mätprojektorer

- Mätmikroskop

- Mikroskopenheter

- Interferometerenheter

- Objektivlinser

- M2 för Mätmikroskop & Projektorer

- TAGLENS

- Fixturer för optisk mätning

- Alla Hårdhetsprovare

- Portabla hårdhetsprovare

- Kombinerade provare

- Vickersprovare

- Automatiska Vickersprovare

- Micro-Vickersprovare

- Programvaror för Hårdhetsprovning

- Testblock och Indenterar

- Alla Sensorsystem, LSM

- Linear Gauges

- Instrument med lågt mättryck

- Räknare och Displayenheter

- Laser Scan Mikrometrar

- Surface Measure

- Programvara för sensorstyrning

- Mikrometrar & Mikrometerhuvuden

- Digitala & Mekaniska mikrometrar

- Tillbehör till mikrometrar

- Mikrometerhuvuden

- Tillbehör till mikrometerhuvuden

- Mätdon för invändig mätning

- Invändiga mikrometrar

- Hålindikatorer

- Tillbehör till mätdon för invändig mätning

- Indikerande mätdon och Skänkelmätur

- Digitala mätur

- Tillbehör till mätur

- Vippindikatorer

- Mätur

- Tillbehör till vippindikatorer

- Tjockleksmätare, Skänkelmätur och Fjädervågar

- Specialutrustning

- Indikatorstativ

- Precisionsskruvstycken

- Planskivor och granitvinklar

- Vinkelmätning

- Bladmått, linjaler

- Passbitar

- Passbitssatser i stål

- Passbitar i stål, styckevis

- Passbitssatser i keramik Cera-Block

- Passbitar i keramik, styckevis

- Specialpassbitar

- Tillbehör till passbitar

- Tillbehör till kvadratiska passbitar

- Små och mellanstora koordinatmätmaskiner

- CRYSTA-Apex V - 500, 700, & 900-serien

- CRYSTA-Apex V - 1200, 1600 & 2000-serien

- CRYSTA-Apex EX-serien för REVO

- STRATO-Active-serien

- STRATO-Apex - 500, 700, & 900-serien

- STRATO-Apex - 1600-serien

- LEGEX-serien

- Mätspetsar

- Mätspetssatser

- Raka mätspetsar

- Diamantbelagda mätspetsar

- Solida diamantmätspetsar

- Masterkulor

- Verktygsmaskinprober

- Stjärnmätspetsar

- Mätspetsar för stjärnmätspets

- Mätspetsar för hållare

- Cylindriska mätspetsar

- Tallriksmätspetsar

- Spetsiga mätspetsar

- Förlängare

- Hållare

- Adaptrar

- Leder

- Skruvar för kubiska hållare

- Verktyg

- StyliCleaner

- Fixturer

- CMM Fixtureringssatser

- Eco-fix Pallettsystem

- FixtureBuilder programvara

- Eco-fix och Eco-fixplus förlängningssatser

- Eco-fix och Eco-fixplus komponenter

- Eco-fix skruvar och verktyg

- 3D CNC Visionsystem

- Quick Vision ACTIVE

- Quick Vision APEX / HYPER

- Quick Vision ACCEL

- Quick Vision ULTRA

- Fixturer för Visionsystem

- Fixtureringssatser för optisk mätning

- Opti-fix-komponenter

- Opti-fix skruvar och verktyg

- Mätspetsar för Visionsystem

- Raka mätspetsar

- Förlängare

- Stjärnmätspetsar

- Hållare

- Mätspetsar för 5-vägsspets

- Mätspetsar för hållare

- Adaptrar

- Leder

- Cylindriska mätspetsar

- Tallriksmätspetsar

- Spetsiga mätspetsar

- Screw for Cube

- Verktyg

- Mätspetssatser

- Mätprojektorer

- PJ-serien

- PV-serien

- PH Series

- Dataprocessor

- Tillbehör

- Verktyg för noggrannhetskontroll

- Mätmikroskop

- TM-serien Gen. B

- MF-serien Gen. D

- MF-U Series Gen. D

- Belysning

- Vision Unit

- QSPAK-VUE Programvara

- Mikroskopkameror

- Objektivlinser

- Objektiv för ML-serien

- Ljusfält Observationsobjektiv

- Ljusfält/Mörkfält Observationsobjektiv

- NIR Objektiv

- NIR LCD Objektiv

- NUV Objektiv

- NUV LCD Objektiv

- UV Objektiv

- UV LCD Objektiv

- Interferometerobjektiv

- Fixturer för optisk mätning

- Fixtureringssatser för optisk mätning

- Opti-fix-komponenter

- Opti-fix skruvar och verktyg

- Ytjämnhet

- Surftest SJ-210

- Surftest SJ-220

- Surftest SJ-310

- Surftest SJ-410

- Surftest SJ-500

- Surftest SV-2100

- Surftest SJ-500P

- Surftest SV-2100P

- Formtracer Avant FTA-S3000

- Surftest Extreme SV-3000CNC

- Surftest Extreme SV-M3000CNC

- Ytjämnhet & Kontur

- Formtracer Avant FTA-D3000 / FTA-D4000-serierna

- Formtracer Avant FTA-H3000

- Formtracer Extreme SV-C4500CNC

- Formtracer Extreme SV-C4500CNC HYBRID Typ 1

- Formtracer Extreme CS-5000CNC och CS-H5000CNC

- Portabla hårdhetsprovare

- Hårdhetsprovare med slagkropp HARDMATIC HH-411

- Digitala och analoga Durometers HARDMATIC HH-300

- Kombinerade provare

- Rockwell HR-200/300/400

- Rockwell, Rockwell Superficial, Brinell Hårdhetsprovare HR-530 och HR-600

- Rockwell Automatisk Hårdhetsprovare HR-600

- Automatiska Vickersprovare

- Automatiska Micro-Vickers Hårdhetsprovarsystem

- Automatiska Vickers Hårdhetsprovarsystem

- Linear Gauges

- ABSOLUTE Digimatic Linear Gauge LGS-serien

- Luftcylinder

- Linear Gauge LG100-serien

- Linear Gauge LG200-serien

- Laser Hologauge

- Räknare och Displayenheter

- EJ-räknare och Interface för Linear Gauges

- EC-räknare för Linear Gauges

- EG-räknare för Linear Gauges

- EH-räknare för Linear Gauges

- EV-räknare för Linear Gauges

- Displayenhet för EV-räknare

- Laser Scan Mikrometrar

- Laser Scan Mikrometer Mätenhet

- Laser Scan Mikrometer Styrenhet

- Laser Scan Mikrometer Interfaceenhet

- Laser Scan Mikrometer Specialtillbehör

- DRO Linear Scales och Räknare

- DRO Linear Scales AT103

- DRO Linear Scales AT103 - Högnoggrann

- DRO Linear Scales AT113

- DRO Linear Scales AT113 - Högnoggrann

- DRO ABS Linear Scales AT715

- Universell DRO KA-200 Räknare

- NC Linear Scales

- NC Linear Scales ST36

- NC Linear Scales ST46-EZA

- NC Linear Scales ABS ST700

- NC Linear Scales ABS ST1300

- NC Linear Scales AT211

- NC Linear Scales ABS AT1100

- NC Linear Scales ABS AT1300

- Skalenheter

- Horisontell ABSOLUTE-skala Coolant Proof IP66

- Horisontell ABSOLUTE-skala Standard

- Horisontell ABSOLUTE-skala Omkastning av mätriktning

- Horisontell ABSOLUTE-skala Diameterfunktion

- Vertikal ABSOLUTE-skala Standard

- Vertikal ABSOLUTE-skala Omkastning av mätriktning

- Vertikal ABSOLUTE-skala Diameterfunktion

- Signalkablar

- USB Input Tool Direct (Digimatic-USB Cable)

- Digimatic Data Cables

- Digimatic Extension Cables

- Trådlös kommunikation

- Wireless Communication System U-WAVE

- U-WAVE Bluetooth

- U-WAVE-T Connection Cables and Connection Units

Flygindustri

Flygindustri

Komplexa flygindustritillämpningar kräver snabb och extremt noggrann kvalitetskontroll för att säkerställa exakta monteringar. Se hur Mitutoyo gör det möjligt.

Fordonsindustri

Fordonsindustri

Bilindustrin fortsätter att utvecklas, och Mitutoyo levererar avancerade inspektions- och skanningsmöjligheter för att hjälpa tillverkare att upprätthålla en kontinuerlig produktion.

Energi

Energi

Mitutoyos mät- och analyslösningar är utformade för att hjälpa energileverantörer att förbättra tillförlitligheten och öka utrustningens drifttid.

Medicinteknik

Medicinteknik

För att skydda patienternas välbefinnande kräver medicinska tillämpningar exceptionell noggrannhet. Se hur noggrant testade lösningar från Mitutoyo kan hjälpa dig att uppnå detta.

Tillverkningsindustrin

Tillverkningsindustrin

Säkerställ hög repeterbarhet och rigorös kvalitetskontroll med formmätningslösningar, koordinatmätmaskiner och precisionsmätverktyg från Mitutoyo.

Elektronik

Elektronik

Mitutoyos beröringsfria och optiska mätlösningar ger mikroskopisk noggrannhet till mindre och kompakt elektroniska komponenter.

Original Equipment Manufacturers (OEM)

Original Equipment Manufacturers (OEM)

Mitutoyo OEM kan åtgärda brister i expertis eller resurser genom att förse er med vår välkända metrologiutrustning som smidigt integreras i era produkter.

Fallstudier

Fallstudier

För en översikt av Mitutoyos kapacitet är vår imponerande samling av fallstudier en utmärkt resurs.

Mitutoyo Japan Desk

Mitutoyo Japan Desk

Det första stoppet för japanska företag som verkar i Europa

Specialprodukter

Specialprodukter

Specialtillverkade produkter för unika applikationer

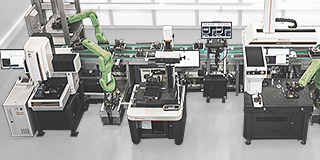

Automationsintegration

Automationsintegration

Förvandla din fabrik till en smart fabrik med hjälp av Mitutoyo

Mitutoyos integratörer

Mitutoyos integratörer

Att integrera dina mätinstrument i befintliga processer har aldrig varit enklare

Reparationer & Reservdelar

Reparationer & Reservdelar

Reservdelar och reparationer för Mitutoyos utrustningar

Kalibrering

Kalibrering

Låt kalibrera dina mätinstrument hos ett laboratorium du litar på.

Fältservice

Fältservice

Service på plats för dina favoritmät- och testutrustningar

Produktdemo

Produktdemo

Online eller offline, få en produktdemonstration idag

IT Support

IT Support

Perfekt och smidig installation samt integrering i din IT-infrastruktur.

Education Pack

Education Pack

Perfekta för verkstaden eller klassrummet – Mitutoyos posters och läromaterial är ovärderliga hjälpmedel.

E-Learning

E-Learning

För de som är intresserade av metrologi erbjuder Mitutoyo E-learning-kurser som hjälp för att utbilda studenter, personal eller andra intresserade.

Filmer

Filmer

Om du letar efter ett snabbt sätt att lära dig mer om mätteknik, titta gärna på våra många instruktionsvideor.

Upptäck Mitutoyo

Upptäck Mitutoyo

Världens största företag inom metrologi

Kontakt

Kontakt

Vid frågor om Mitutoyos produkter, kontakta oss på telefonnummer 08-594 109 50 eller via e-post kontakt@mitutoyo.se

Jobba hos oss

Jobba hos oss

Lär dig mer om hur det är att arbeta på Mitutoyo och vilka steg du kan ta för att starta din karriär hos oss.

Mässor & Events

Mässor & Events

Håll dig uppdaterad med evenemang runt om i Europa och besök oss för att se de senaste nyheterna från Mitutoyo!

Pressinformation

Pressinformation

Se våra senaste nyheter och andra uppdateringar

Produktbroschyrer

Produktbroschyrer

Visa och ladda ner vår katalog, produktbroschyrer och mycket mer

Programvaror

Programvaror

Ladda enkelt och smidigt ner programvaror och uppdateringar

Declarations of Conformity

Declarations of Conformity

Här kan du ladda ner fullständiga versioner för EU och Storbritannien

Gratis posterbilder

Gratis posterbilder

Ladda ner officiella Mitutoyo-bakgrundsbilder gratis

Mitutoyos kommunikationsmaterial

Mitutoyos kommunikationsmaterial

Resurser för Mitutoyos personal och externa leverantörer

Online-katalog

Online-katalog

Visa vårt omfattande produktutbud i vår Online-katalog!

-

Produkter

- Tillbaka Produkter

- Produkter

- Utvalda produkter

- Produkter efter Industri

-

Handmätdon

- Tillbaka Handmätdon Alla Handmätdon

- Skjutmått

-

Mikrometrar & Mikrometerhuvuden

- Tillbaka Mikrometrar & Mikrometerhuvuden Mikrometrar & Mikrometerhuvuden

- Digitala & Mekaniska mikrometrar

- Tillbehör till mikrometrar

- Mikrometerhuvuden

- Tillbehör till mikrometerhuvuden

-

Mätdon för invändig mätning

- Tillbaka Mätdon för invändig mätning Mätdon för invändig mätning

- Invändiga mikrometrar

- Hålindikatorer

- Tillbehör till mätdon för invändig mätning

-

Mätdon för djupmätning

- Tillbaka Mätdon för djupmätning Mätdon för djupmätning

- Djupmikrometrar

- Djupmått

- Tillbehör till djupmått

- Höjdmått

-

Indikerande mätdon och Skänkelmätur

- Tillbaka Indikerande mätdon och Skänkelmätur Indikerande mätdon och Skänkelmätur

- Digitala mätur

- Tillbehör till mätur

- Vippindikatorer

- Mätur

- Tillbehör till vippindikatorer

- Tjockleksmätare, Skänkelmätur och Fjädervågar

- Specialutrustning

-

Utrustning för kalibrering

- Tillbaka Utrustning för kalibrering Utrustning för kalibrering

- Height Masters

- Check Masters

- Kalibreringsutrustning

- Passbitar

-

Koordinatmätmaskiner

- Tillbaka Koordinatmätmaskiner Alla Koordinatmätmaskiner

- Små och mellanstora koordinatmätmaskiner

-

Koordinatmätmaskiner för inline-mätning

- Tillbaka Koordinatmätmaskiner för inline-mätning Koordinatmätmaskiner för inline-mätning

- MACH Ko-ga-me

- MACH 3A 653

- MACH V 9106

- MiSTAR 555

-

Stora koordinatmätmaskiner

- Tillbaka Stora koordinatmätmaskiner Stora koordinatmätmaskiner

- STRATO Apex G

- CARB-serien

-

CMM Rotationsbord

- Tillbaka CMM Rotationsbord CMM Rotationsbord

- MRT240 Rotationsbord

- MRT320 Rotationsbord

- Prober

-

Mätspetsar

- Tillbaka Mätspetsar Mätspetsar

- Mätspetssatser

- Raka mätspetsar

- Diamantbelagda mätspetsar

- Solida diamantmätspetsar

- Masterkulor

- Verktygsmaskinprober

- Stjärnmätspetsar

- Mätspetsar för stjärnmätspets

- Mätspetsar för hållare

- Cylindriska mätspetsar

- Tallriksmätspetsar

- Spetsiga mätspetsar

- Förlängare

- Hållare

- Adaptrar

- Leder

- Skruvar för kubiska hållare

- Verktyg

- StyliCleaner

- Fixturer

-

Inkapslingar

- Tillbaka Inkapslingar Inkapslingar

- CMM Enclosures

-

CMM Programvara

- Tillbaka CMM Programvara CMM Programvara

- MiCAT Planner

- MCOSMOS

- MAFIS Express

- MSURF

-

Visionmätsystem

- Tillbaka Visionmätsystem Alla Visionmätsystem

-

Manuella 2D Visionsystem

- Tillbaka Manuella 2D Visionsystem Manuella 2D Visionsystem

- Quick Image

- Quick Image programvara

-

Manuella 3D Visionsystem

- Tillbaka Manuella 3D Visionsystem Manuella 3D Visionsystem

- Manuell Quick Scope

- Quick Scope programvara

- 3D CNC Visionsystem

-

3D CNC Multisensor Visionsystem

- Tillbaka 3D CNC Multisensor Visionsystem 3D CNC Multisensor Visionsystem

- Quick Vision Hybrid

- Quick Vision WLI

-

MiSCAN Visionsystem

- Tillbaka MiSCAN Visionsystem MiSCAN Visionsystem

- MiSCAN APEX 404

- MiSCAN HYPER 302

- MiSCAN HYPER 404

-

3D CNC Visionsystem för mikrogeometrier

- Tillbaka 3D CNC Visionsystem för mikrogeometrier 3D CNC Visionsystem för mikrogeometrier

- UMAP Visionsystem

- UMAP programvara

-

Vision System Software

- Tillbaka Vision System Software Vision System Software

- QVPAK

- QSPAK

- QIPAK

- Tillbehör till Visionsystem

-

Fixturer för Visionsystem

- Tillbaka Fixturer för Visionsystem Fixturer för Visionsystem

- Fixtureringssatser för optisk mätning

- Opti-fix-komponenter

- Opti-fix skruvar och verktyg

- Mätspetsar för Visionsystem

-

Optiska mätsystem

- Tillbaka Optiska mätsystem Alla Optiska mätsystem

- Luppar

- Mätprojektorer

- Mätmikroskop

- Mikroskopenheter

- Interferometerenheter

- Objektivlinser

- M2 för Mätmikroskop & Projektorer

- TAGLENS

-

Fixturer för optisk mätning

- Tillbaka Fixturer för optisk mätning Fixturer för optisk mätning

- Fixtureringssatser för optisk mätning

- Opti-fix-komponenter

- Opti-fix skruvar och verktyg

-

Formmätning

- Tillbaka Formmätning Alla Formmätning

- Ytjämnhet

- Kontur

- Ytjämnhet & Kontur

-

Form

- Tillbaka Form Form

- Roundtest

- Roundtracer

-

FMI Programvara

- Tillbaka FMI Programvara FMI Programvara

- Formtracepak

- Roundpak

-

Fixturer

- Tillbaka Fixturer Fixturer

- Eco-fix FMI satser

-

Hårdhetsprovare

- Tillbaka Hårdhetsprovare Alla Hårdhetsprovare

- Portabla hårdhetsprovare

- Kombinerade provare

-

Vickersprovare

- Tillbaka Vickersprovare Vickersprovare

- Vickers Hårdhetsprovare HV-110/120

-

Automatiska Vickersprovare

- Tillbaka Automatiska Vickersprovare Automatiska Vickersprovare

- Automatiska Micro-Vickers Hårdhetsprovarsystem

- Automatiska Vickers Hårdhetsprovarsystem

-

Micro-Vickersprovare

- Tillbaka Micro-Vickersprovare Micro-Vickersprovare

- Micro-Vickers Hårdhetsprovare HM-210/220

-

Programvaror för Hårdhetsprovning

- Tillbaka Programvaror för Hårdhetsprovning Programvaror för Hårdhetsprovning

- AVPAK

-

Testblock och Indenterar

- Tillbaka Testblock och Indenterar Testblock och Indenterar

- Testblock

- Indentrar och utbyteskulor

-

Sensorsystem, LSM

- Tillbaka Sensorsystem, LSM Alla Sensorsystem, LSM

- Linear Gauges

-

Instrument med lågt mättryck

- Tillbaka Instrument med lågt mättryck Instrument med lågt mättryck

- LITEMATIC VL-50 Motoriserat lågt mättryck, högnoggrann

- Räknare och Displayenheter

- Laser Scan Mikrometrar

-

Surface Measure

- Tillbaka Surface Measure Surface Measure

- Surface Measure 1008S

- Surface Measure 0303S

- Tillbehör

- Programvara för sensorstyrning

-

Skalenheter och Linear Scale

- Tillbaka Skalenheter och Linear Scale Alla Skalenheter och Linear Scale

- DRO Linear Scales och Räknare

- NC Linear Scales

-

Skalenheter

- Tillbaka Skalenheter Skalenheter

- Horisontell ABSOLUTE-skala Coolant Proof IP66

- Horisontell ABSOLUTE-skala Standard

- Horisontell ABSOLUTE-skala Omkastning av mätriktning

- Horisontell ABSOLUTE-skala Diameterfunktion

- Vertikal ABSOLUTE-skala Standard

- Vertikal ABSOLUTE-skala Omkastning av mätriktning

- Vertikal ABSOLUTE-skala Diameterfunktion

-

Datahantering

- Tillbaka Datahantering Alla Datahantering

-

Programvara för mätdatahantering

- Tillbaka Programvara för mätdatahantering Programvara för mätdatahantering

- MeasurLink 10

- USB-ITPAK

-

Miniprocessor

- Tillbaka Miniprocessor Miniprocessor

- Digimatic Mini Processor DP-1VA LOGGER

- Signalkablar

- Trådlös kommunikation

- Interface

-

Timerbox, Digimatic Mätdonsväljare

- Tillbaka Timerbox, Digimatic Mätdonsväljare Timerbox, Digimatic Mätdonsväljare

- Digimatic Timerbox

- Digimatic Switch Box

-

Programvaror

- Tillbaka Programvaror Alla Programvaror

-

Programvaror för CMM

- Tillbaka Programvaror för CMM Programvaror för CMM

- MiCAT Planner

- MCOSMOS

- MAFIS-Express

- MSURF

-

Programvaror för Visionsystem

- Tillbaka Programvaror för Visionsystem Programvaror för Visionsystem

- QVPAK

- QSPAK

- QIPAK

-

Programvaror för Formmätning

- Tillbaka Programvaror för Formmätning Programvaror för Formmätning

- Formtracepak

- Roundpak

- Programvaror för Hårdhetsprovning

- Programvaror för Sensorstyrning

-

Programvaror för mätdatahantering

- Tillbaka Programvaror för mätdatahantering Programvaror för mätdatahantering

- Measurlink 10

- USB-ITPAK

- Datoriserade Tomografisystem

- Industrier

- Tjänster

-

Utbildning

- Tillbaka Utbildning

- Utbildning

- Education Pack

- E-Learning

- Filmer

- Om oss

-

Nyheter & Aktiviteter

- Tillbaka Nyheter & Aktiviteter

- Nyheter & Aktiviteter

-

Mässor & Events

- Tillbaka Mässor & Events

- Mässor & Events

-

Specialerbjudanden

- Tillbaka Specialerbjudanden

- Specialerbjudanden

- Pressinformation

- Ladda ner

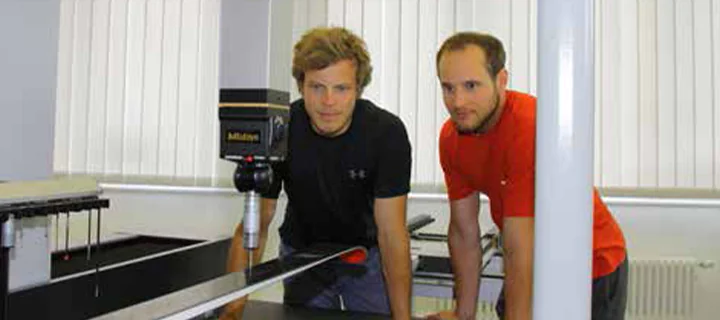

Fancier workpieces have rarely been measured by a coordinate measuring machine: Two Austrian students have been checking, as part of a student research project, the carving of GS (Giant Slalom) racing skis with a Mitutoyo Crysta-Apex S.

Their passion for the project is easy to see in Mario Lazzeri and Johannes Brunner, because the two Austrian students have devised a more than exotic theme for their student research project. They measure GS racing skis. Their goal is to find out whether the relatively simple method of measurement of the international ski federation, FIS, is feasible and provides realistic results, or not. To be exact, this has to do with the carving of the skis, i.e. the concavity of the ski edges. Modern “planks” are namely wider at the leading and trailing ends than in the middle. This special “carved” form facilitates and speeds up cornering - for both hobby skiers as well as for World Cup Professionals.

The FIS regulations stipulate an average radius of curve of at least 35 meters in the giant slalom. Although tighter radii comply with the dynamics they do, however, pose an increased risk of injury to the skier. Furthermore, the skis must be at least 1.95 meters long. The skis are measured in the developed length by the FIS with a steel measuring tape, the zero point of which is attached to the end of the ski.

The length of the ski is then measured from the narrowest point of the ski to the leading and trailing ends. In order that the entire ski waist radius is not distorted by the different geometries of the ski tails and ski tips, the rear ski width is measured for 90% of the rear ski length and the leading ski width for 80% of the front ski length. In order to determine the sidecut the width of the ski is measured – at predetermined points – using a movable device with a built-in sliding caliper. Using an integrated magnifying glass with a marking line, the measurement position can be read from the measuring tape. From this, the mean radius of the sidecut is calculated.

If the sidecut radius is found to be under the permitted limit after a single measurement, the measurement and calculation has to be repeated twice. From the thus determined three sidecut radii the arithmetic mean, XR, is generated. To allow for measurement errors in the length and the width the sidecut radius is defined as 1.015 XR. This corresponds to an average measurement error of 1.5%. 1.015 XR must be greater than or equal to the applicable radius limitation.

"Measuring with a caliper at different positions has enormous potential for error," said Lazzeri. "We want to know if the results are useful and reliable or not," says the trained machinist. Thus was born the idea for the student research project for the seminar "Problem Analysis in Biomechanics" at the Institute of Sports Sciences at the University of Innsbruck in Univ.-Prof. Mag. Dr. Werner Nachbauer.

The issue is dynamite, because a supposedly too small a radius may result in a disqualification by the FIS – and can result in a tremendous setback both sportswise and financially for the athlete and his team.

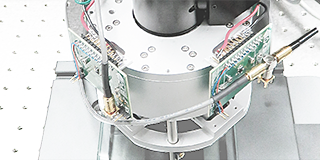

Since Lazzeri had worked half his life with Mitutoyo manual measurement tools, the 31-year-old knew that the Japanese are the benchmark worldwide in terms of dimensional metrology. A phone call was enough: Mitutoyo Austria was in on the party and supported the project with help and advice. The skis were measured in the Mitutoyo branch at Eisenach. Together with Mitutoyo engineer, Friedrich Schinko, the skis were harnessed to a coordinate measuring machine of the type Mitutoyo Crysta-Apex S 9168 with a tactile scanning probe SP25. To fix the skis on the granite working table of the Crysta the Austrians had specially converted a mount for ski bindings, similar to that used by the service staff to grind the steel edges.

After a pre-probing from above for each measuring point, the Crysta-Apex S executed the edge point measurement with a travel speed of 520 mm/s and a digital step of 0.1 microns, with a cylindrical stylus tip of four millimeters diameter. With the extremely powerful Mitutoyo CMM software MCOSMOS, Lazzeri, Brunner and Schinko collected and analysed the data, because MCOSMOS is ideal for this purpose with the universal geometry measurement program GEOPAK with macros for the automatic measurement of all control geometries and the 2D evaluation module SCANPAK.

The software depicted graphically every single one of the probe starting points together with all the relevant data. From all the individual data delivered by the Crysta-Apex S it was not only the overall radius of the ski that could be reliably calculated, but also the pretension of the ski, the tip radius, any form deviations of the overall radius and individual radii from at least 3 points in each case.

After two days of testing and a meticulous data analysis, the verdict of the students was made. With regard to the carving there are serious differences between the different racing skis. Within the limitations of the regulations every manufacturer is obviously trying, with his own design, to optimise the dynamic behavior of his skis. The FIS method of using calipers showed, with respect to a calculated average sidecut radius, no significant deviation from the measurement with the Mitutoyo Crysta-Apex S and thus serves its purpose. Statements about sidecut development cannot, however, thus be met. For this, measurement by coordinate metrology would be indispensable.